„I want to build the best and most valuable guitars money can buy while maximizing environmental sustainability.“

Vita

Since I was a little boy, I have been enthusiastically carving on pieces of wood and always „invented“ new things. As a teenager in the 80s, my hobby was to build music electronics (amplifiers, effect pedals, synthesizers, …) and to repair guitars. After graduating from high school, I completed a solid education as an electrical engineer and business engineer and gained 30 years of experience in the development of electronics and interiors in racing cars and production cars. Along the way, I steadily expanded my knowledge of guitar building and learned many topics about it from automotive development and many well-known craftsmen. Over the decades I found my own way, rethought numerous topics and processes in guitar building and developed my own solutions.

Main idea

Every day, the exploration of the universe shows anew that there is still much to discover in our cosmos and that we are surrounded by far more unknown than familiar. Anyone who has ever looked at the infinite variety of stars through a telescope on a clear night will never forget the sight. It makes you realize how small and unimportant we are. To express my fascination for our universe, I give all my guitars names of cosmic objects.

Even in the physics of the guitar, there is still much to discover. Only by breaking new ground can new sound dimensions be opened up. Without missing the due respect for the well-known guitar classics, I do not want to copy them, but consciously but consciously develop new concepts. There are endless possibilities to develop or optimize the technique in a new way, if one does not have to take history into consideration. But pursuing new approaches does not necessarily mean ignoring the experience of traditional craftsmanship. Mankind has built up a wealth of experience of immeasurable value here over centuries, which is unfortunately increasingly being lost in many places through the use of industrial manufacturing technologies.

Sustainability

After I like to call man the biggest pest on earth, I at least try to keep my ecological footprint as small as possible.

Our house with integrated workshop meets the highest possible standards regarding ecological construction at the time of construction. For years we have been using only green electricity and since 2023 we have also been producing our own electricity via a PV system. The water for the garden and the toilet flush has always come from our rainwater cistern.

In guitar building I try as far as possible to use only natural materials such as wood, metal, bone, pearl, leather, stones and glass. Above all, it is important to me to avoid lacquers and plastics as far as possible.

Another aspect of sustainability is the reduction of primary energy use. By using local woods, energy for transport is saved and at the same time the rainforests are conserved. Wherever possible, I only use woods that have been air-dried for many years. These are significantly freer from internal stresses and in addition, energy is again saved compared to chamber drying.

As far as available, I also use reclaimed woods. A 50-year-old tabletop or staircase is well aged and ideal for guitar making. Here you can then also use tropical woods. Still better than if these would be thermally disposed of.

Workshop

To provide superior manufacturing quality, I have optimized all operations over the years, comparing different methods and always opting for the best alternative. Whereby the best alternative uncompromisingly means the method that provides the best results and not the one that allows the shortest working time.

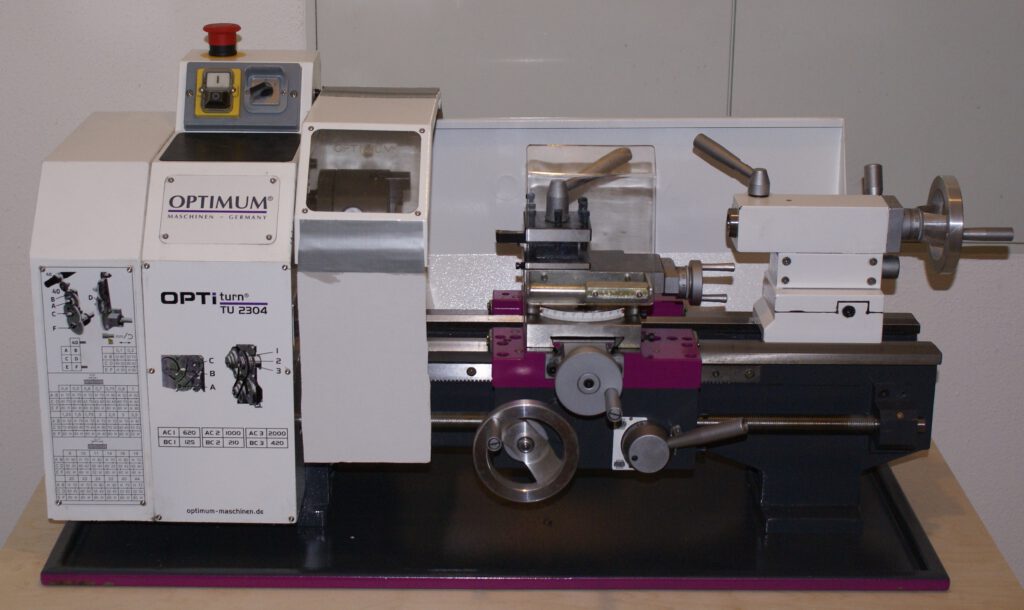

For the craft activities I use the usual woodworking and metalworking machines.

Pure manual work, the main scope of my guitar building, I prefer to do at my mobile carving and working table, which I can always set up just where the best light is and where I prefer to work.

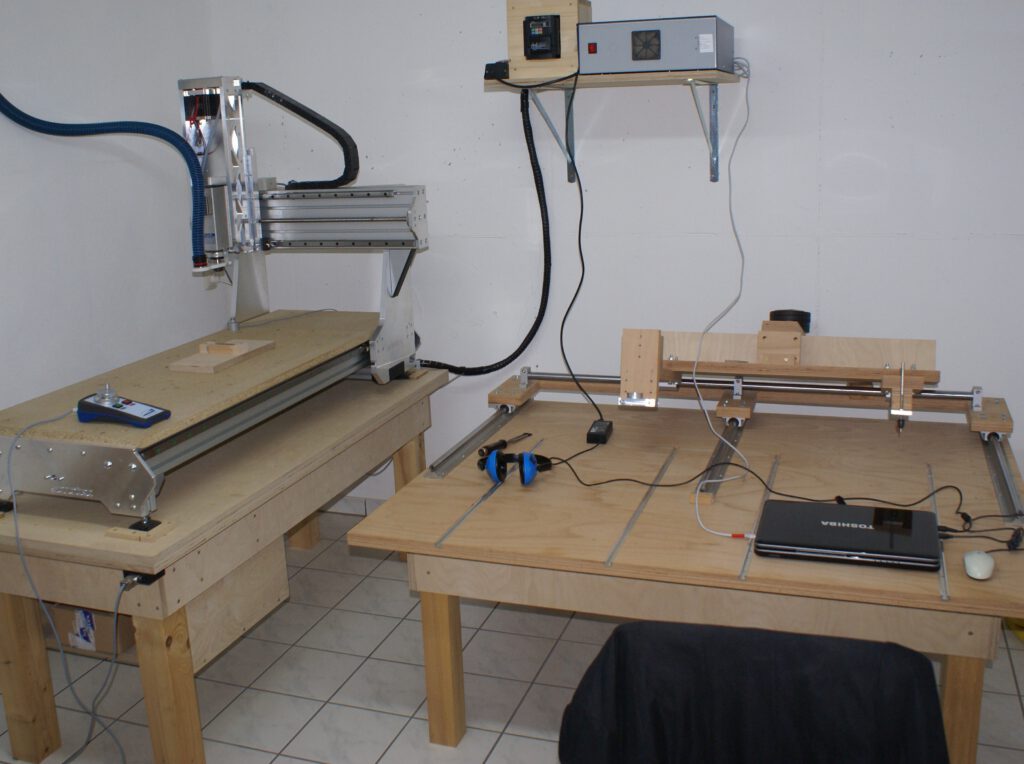

CNC router and copy router are used for initial rough machining, various high-precision work such as hidden fret slots and inlays.

Copyright © 2008-2026 Peter Bachmaier